Reactor Safety

Safety is the number one priority in ABWR design. Nuclear power has an excellent safety record in the UK and continues to operate across 8 sites in England, Scotland and Wales.

Most nuclear stations operate safely throughout their many decades of generation. However incidents such as Fukushima in 2011 understandably bring safety sharply into focus. The UK ABWR meets well-established, international criteria on safety and includes comprehensive features to ensure safety at all times, both during normal operation and under a range of potential accident conditions, from minor to extreme events. These features were one of the key areas considered under the Generic Design Assessment, and the design has been further refined as a result.

Full details on the safety assessments of the UK ABWR through GDA are available via the ‘Library’ page of this website.

Read more about UK ABWR safety measures, severe accidents and lessons learned from Fukushima

The safety features of the UK ABWR are based on a Defence in Depth or ‘redundant measures’ approach. This ensures that there are multiple layers of protection with all layers designed to ensure safety independently of each other.

There are three main steps which are necessary to achieve and maintain a safe state of shutdown during and following an emergency:

- To effectively shut down the operating reactors and end the nuclear reaction.

- To cool the reactors (which reach high temperatures during operation), and maintain cooling for the fuel which will continue to produce heat at a lower rate after shutdown because of the high levels of radioactivity present in the fuel.

- To ensure continued containment of radioactivity.

Further improvements were made to the reactor design incorporating lessons learned from the Fukushima accident of March 2011, with a particular focus on prevention of a complete loss of power on site (known as a Station Black Out) and loss of all cooling options (known as the loss of Ultimate Heat Sink).

To shut down operating reactors

In the event that an emergency shutdown is needed, Control Rods are immediately driven hydraulically into the reactor by high-pressure nitrogen, shutting it down. As a back-up system, water infused with boron (borated water) can also be injected directly onto the reactor core by the Standby Liquid Control System, which stops the fission reaction.

To cool down reactors

The UK ABWR core is cooled in normal operation by the same water circulation that takes place to make steam to spin the turbine. To ensure continued cooling, whether in operation or shutdown, it is important to have secure water supplies, and power to the pumps to circulate this water through the reactor. If cooling is lost, the Emergency Core Cooling Systems are activated to inject coolant into the reactor. Each active component is powered by emergency power sources which are available even if offsite power is lost.

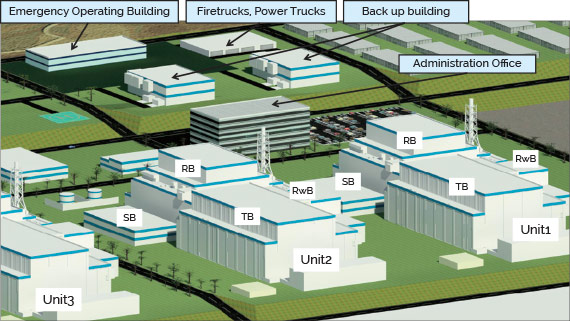

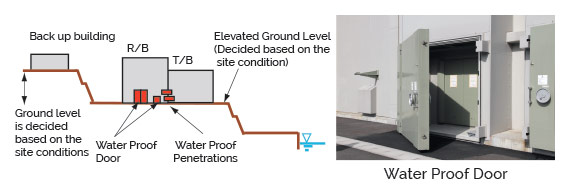

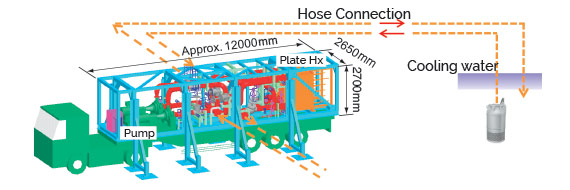

The UK ABWR has a range of water injection options, and if normal cooling is lost, the reactor can be cooled using portable pumps which can be brought to site from nearby equipment stores that the site operator will maintain. There are also multiple options for powering the cooling systems, including back-up power sources encased in flood-protected buildings and the ability to run from alternate power sources. These cooling systems also provide back-up to maintain cooling of the Spent Fuel Storage Pool (SFSP) which keeps the spent fuel in a safe state.

To contain radioactive materials

The UK ABWR has multiple layers of containment. These are designed to ensure that in the event of an incident, all potentially hazardous materials are physically contained within the reactor building.

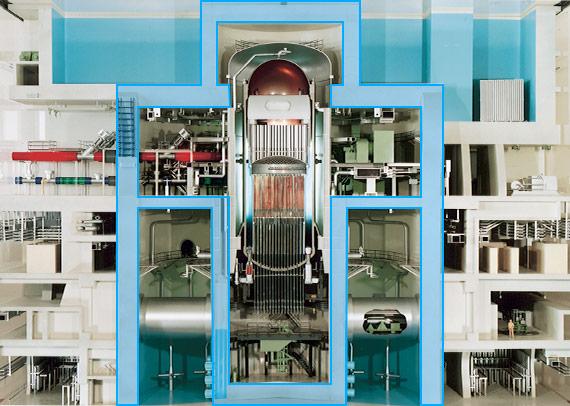

The fuel used within the ABWR is enriched uranium dioxide fuel which is formed of a ceramic type material. Most of the radioactivity remains locked up inside this ceramic material during operation. The fuel material is contained within high integrity metal cladding containers which will not leak in most circumstances, even following an accident. The ABWR uses one of the most advanced fuel designs in the world which has been developed with 50 years of operational experience and improvements and is engineered to the highest quality. The fuel containers are then placed inside multiple barriers, the first of which is the Reactor Pressure Vessel (RPV).

The Reactor Pressure Vessel (RPV) itself is a welded steel vessel, designed to withstand extremely high temperatures and pressures, well beyond the normal operations of the reactor.

This is contained within a Reinforced Concrete Containment Vessel (RCCV). In the unlikely event that hazardous materials are released from the RPV they will be contained within the RCCV and not released to the wider environment. The RCCV consists of a steel liner inside a reinforced concrete structure, designed to withstand external factors such as pressure, heat and extreme damage.

The RCCV itself is contained within the reactor building, providing a third barrier between the radiation and the external environment.

Alongside these key areas, there are a wide number of flexible and effective facilities to help ensure safe operations.

Lessons learned following Fukushima

The UK ABWR has benefited from the continuous development of each generation of BWRs through design improvement and extensive operating experience achieved in Japan and internationally.

This has led to improvement in terms of safety, environmental aspects, security and operational performance.

Following the events at the Fukushima Dai’ichi Nuclear Power Plant, the existing operating plants have been subjected to a rigorous process of evaluation to confirm the resilience of the design against extreme events (this is referred to internationally as Stress Tests). Lessons learnt from this evaluation have led to further improvements to existing plants and these lessons learnt have similarly led to some additional design improvements to be considered for the UK ABWR.

These threats have been further assessed throughout the GDA, and satisfying the regulators of the plant’s ability to withstand such threats was a prerequisite of receiving DAC and SoDA.

The ‘Library’ page of this website provides extensive detail on the measures in place to guard against such hazards, along with a link to the regulators’ published assessment reports.

Measures outlined in these documents include means of connecting external power sources and external cooling water to the reactor building. These assure cooling can be maintained for the reactor and the Spent Fuel Storage Pool, providing further resilience against Station Black Out (SBO) and Loss of Ultimate Heat Sink (LUHS).